News

15. November 2015

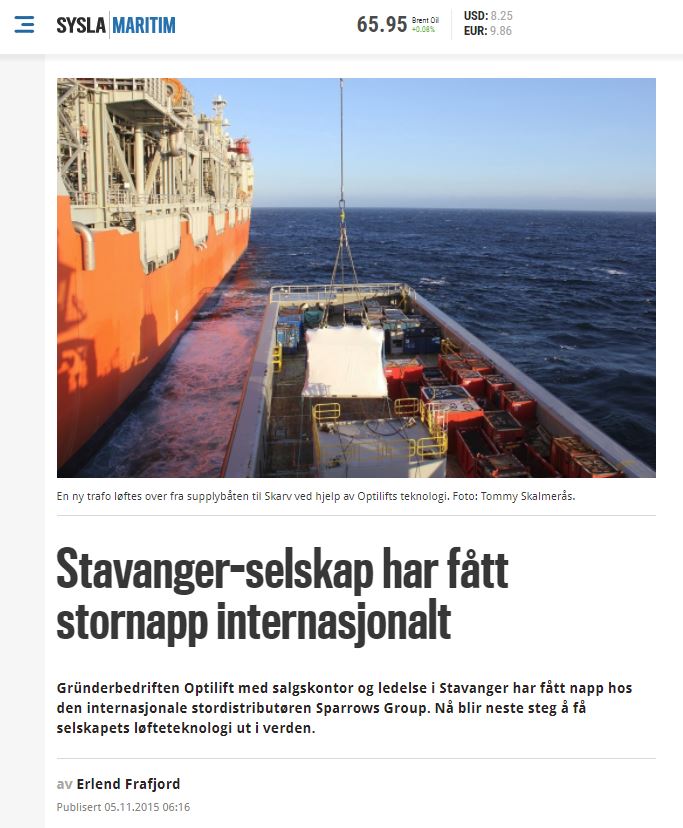

Collaboration between Sparrows Group and OptiLift

Traditionally decisions about lifting in harsh weather are based on significant wave height but OptiLift’s Motion Reporter collects real time vessel movements which identify the actual wave height on deck which often varies by several metres on different parts of the vessel.

Having possession of this important data means crews can make informed decisions about safely continuing lifting operations and avoiding unnecessary costly delays.

The Motion Reporter is a unique piece of technology that works using a laser and camera that automatically generate 3D models of supply vessels without any sensors or instrumentation required to be on the vessel itself.

As part of the agreement, Sparrows Group will distribute, install and maintain the Motion Reporter on behalf of OptiLift.

Stewart Mitchell, chief executive officer of Sparrows Group, said: “Joining forces with OptiLift significantly enhances our capabilities because they have developed a huge innovation in lifting technology. OptiLift’s Motion Reporter could dramatically increase operational efficiency, especially in harsh environments where having the ability to mitigate the risk of the weather delaying your lifting operations is absolutely invaluable.

“By combining Sparrows’ 40 years of experience in lifting operations in the challenging environment of the North Sea with OptiLift’s innovative and unique approach to lifting technology, we can deliver increased efficiency and reduced costs without compromising on safety.”

Camilla Nylund, General Manager at OptiLift said: “We are excited to be working with a partner as experienced and knowledgeable as Sparrows. The Motion Reporter can change the norm of lifting operations in harsh environments, allowing operators to undertake the loading and discharging of cargo quickly and securely, without having to wait for days to know it’s safe to do so. As the world leader in global lifting operations, Sparrows can ensure the technology is used to its full advantage.”

Read the article at Sysla.no about the collaboration agreement here (in Norwegian). The press-release from Sparrows Group is available here.